カサイ工業株式会社

Kasai Industry Co. Ltd.

Welcome

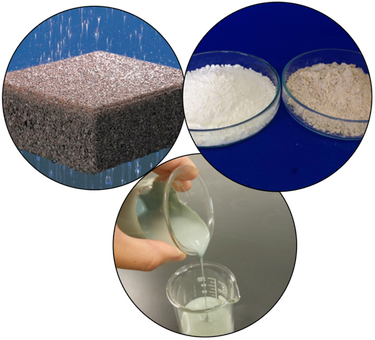

Glaze is applied to the surface of pottery, porcelain and enamel and provides resistance from weather, heat, abrasion and chemical damage. Glaze is a glass coating that has been applied from ancient times in order to achieve a hard and strong surface. Today, the use of ceramics has expanded to industrial products and many other fields.

Made from natural minerals and chemicals, glaze is painted to coat the surface of porcelain and pottery in a slip state before firing.

The high temperature firing changes the glaze to a vitreous coating. It is important that the glaze has appropriate liquidity to both control the thickness of the layer and to achieve operational efficiencies.

The final appearance and characteristics of the glass coating are dependent on the ingredients of the glaze and the firing and cooling processes, all of which affect the chemical reactions and precipitations to vary the type and amount of the resultant glass and crystal structures.

Environmental friendliness is our top priority to be achieved both during the manufacturing process and in the resulting product. We continue to invest in technologies to reduce waste and harmful effects to the environment.

We constantly monitor and improve our technological capabilities to meet our customers’ requirements as a responsible ceramic glaze manufacturer.

Apart from the glaze industry, we invent new ceramic materials to meet the unique requirements and physical and chemical characteristics of new products in many other industries. Our aim is to continue the development and supply of our products by leveraging our expertise in ceramic glaze and its component technologies in combination with cutting edge techniques.

Glaze

Not only dominant in clay roof tile glazes, our glazes have a wide variety of other uses. Click here to learn more.

Frit

Frit is a mixture of silica and flux that is fused at high temperature to make a glass compound uses to make glazes. We specialize in creating flit both for glaze and other projects. Click here to learn more.

Iconic bricks

Our iconographic / pictographic bricks can be ideal for a wide variety of uses in public spaces, factories, schools, churches and homes. Click here to learn more.

Water-permeable Pavement

We create a wide variety of eco-friendly bricks for landscaping, including water-permeable pavement slabs, which are ideal for pedestrian walkways and town squares. Click here to learn more.