Technology - High temperature solid state chemistry

Ceramics and prepared by reacting the raw material powder at a high temperature. The powder particles together in dense coupled to form as a solid to create a ceramic material of purpose. Or contact portion of the raw material particles with each other in contact with (interface) and diffusion of atoms and ions, are particles with each other so that the surface of the particles decreases will continue to coalesce. This is known as sintering.

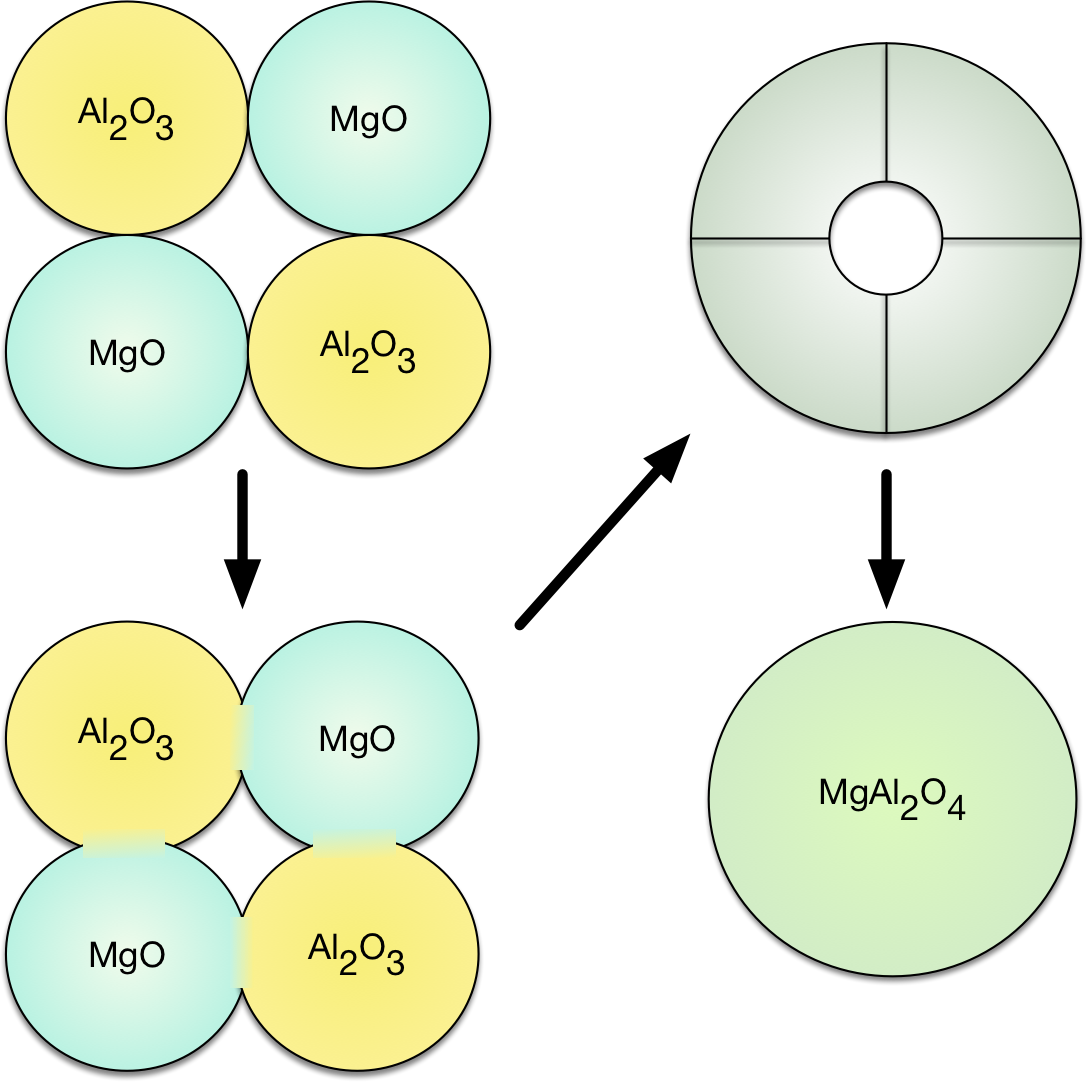

The powder mixture from different materials to obtain a desired material by sintering, that is called reaction sintering the case with the reaction during sintering. Further, when the liquid phase is generated by the sintering process, the liquid phase or is accelerated movement of the working surface tension atomic ions between the particles that penetrate by capillary action, the solid phase is dissolved and re-precipitated in the liquid phase sintering is promoted for. This liquid phase is referred to contribute sintering and liquid phase sintering.

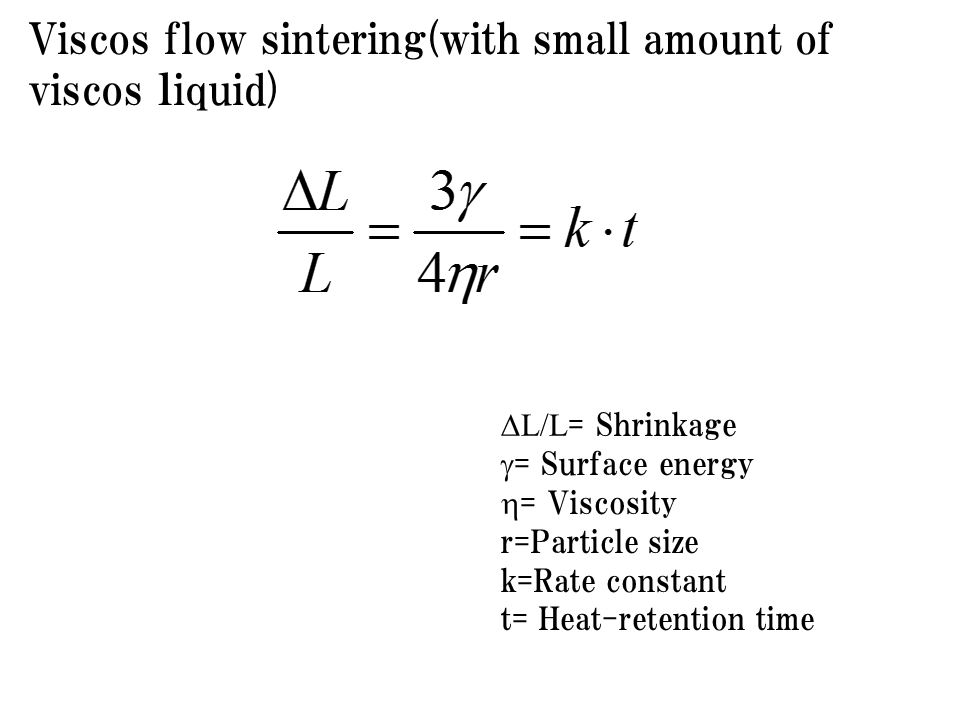

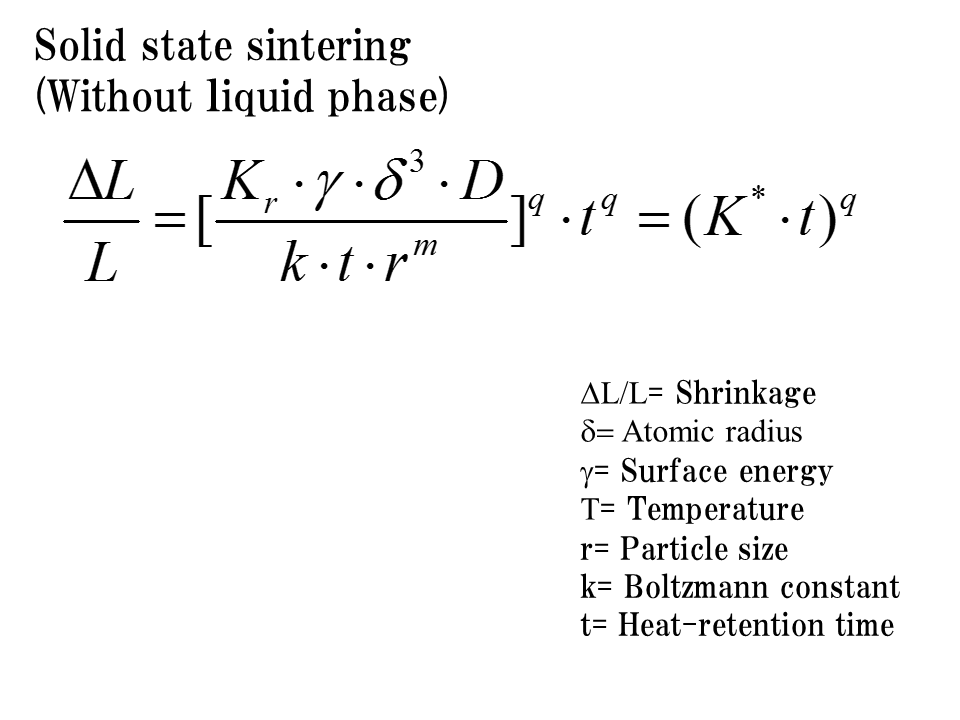

Each of the sintering mechanism is organized by various researchers, sintering rate will proceed largely as shown in Equation.

Particle size of the powder to be used as a raw material in any kind of sintering is that a significant impact on densification (reaction) I think that can be estimated from the equation.

Viscous flow sintering

(with small amounts of viscous liquid)

Solid state sintering

(without liquid phase)

Reaction Sintering behavior of Al2O3 particles